Creating a Shop

I started designing furniture during my Industrial Design undergrad and eventually worked as a research assistant at GA Tech’s Advanced Wood Products Laboratory (AWPL). That experience gave me a taste for digital fabrication using large format CNC equipment, so after I graduated my goal was to recreate that experience so I could get back to building my own furniture designs. I finally pulled it off in 2017 when we moved into a house with a 600sqft shop building - it needed a lot of work but the process of designing the space and building it out was almost as much fun as any of the projects I’ve completed in it since.

Starting from an empty, uninsulated building with a small electrical service, I’ve created a really nice work space with traditional and CNC woodworking equipment. The shop includes an AvidCNC 4896 Pro CNC router, planer, jointer, tablesaw, drum sander, belt sander, and bandsaw. I also built a dust collection system that’s plumbed into all the larger pieces of equipment.

This was the shop right after we moved in - first steps were ripping out the existing wiring, fixing some structural issues, then getting insulation sprayed in.

Once we got insulation and installed lighting (Lithonia IBGs from Acuity Brands Lighting!), equipment started rolling in from a combination of Craigslist and industrial auctions.

With the help of an electrician friend, I ran a new 80amp electrical service to the shop from our house. Here we've trenched in and run a new conduit for the cable.

AvidCNC PRO4896 router frame ruing assembly. This shipped as a kit and I assembled it in its final spot. The X and Y axes are actuated by a rack and pinion, and the Z axis uses a sealed ball screw.

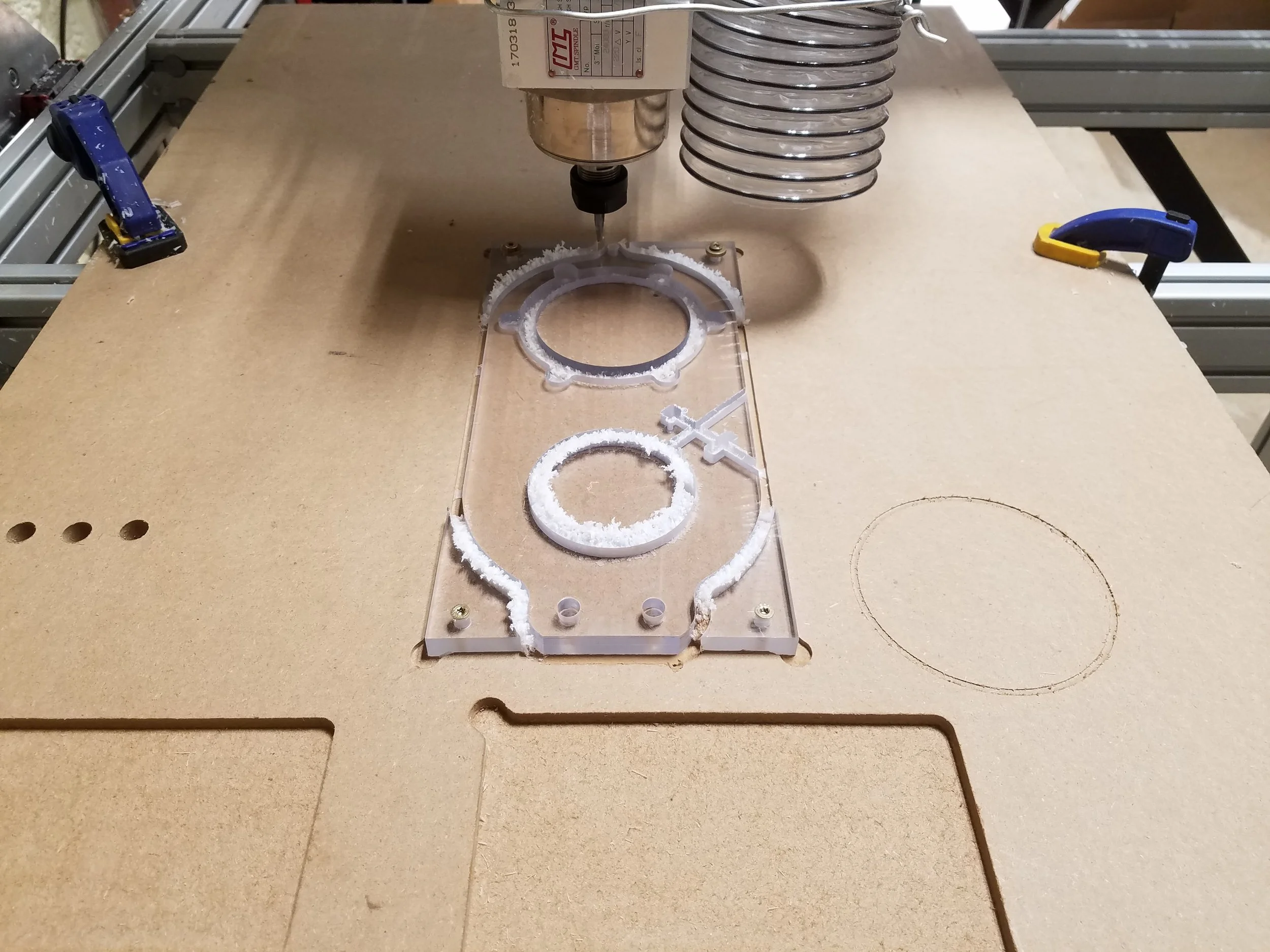

This was the first project I made on the router - I designed a dust hood for the spindle and cut it out of 1/2" polycarbonate sheet.